Key Benefits of Sea food freezing machine

Preserves Freshness & Quality

Rapid freezing prevents large ice crystal formation, protecting cell structure.

Maintains taste, texture, and nutritional value better than slow freezing.

Prevents Clumping

Unlike traditional freezing, IQF keeps each piece (e.g., berries, vegetables, seafood) separate, making portioning easier.

Year-Round Availability

Enables access to seasonal produce anytime without compromising quality.

Reduces food waste by extending shelf life while retaining freshness.

d.Convenience & Affordability

Eliminates the need for preservatives since freezing naturally preserves food.

Saves time in meal prep while offering near-fresh quality.

e. Versatility

Works well for fruits, vegetables, seafood, meat, and even prepared meals.

BS series Individual Fluidized Freezing machine

The BS series Individual Quick Freezer conveys materials with stainless steel wire mesh belts. During the conveying process, the materials undergo heat exchange through top, forward and reverse air blowing to achieve rapid freezing.

This series of Individual Quick Freezer are suitable for freezing mainly including processed foods such as spring rolls and shumai, meat products such as cut meat, meat skewers, chicken legs and chicken wings, aquatic products such as shrimp, fish slices and shellfish, and fruit and vegetable products such as asparagus.

Main technical parameters of BS Individual Quick Freezer

Low feed height, easy maintenance, conveyor belt is divided into one and two sections, can be selected according to different products.

| Model of Individual Quick Freezer | BS300 | BS500 | BS1000 |

| Freezing capacity (kg/h) | 300(Headless shrimp) | 500(Headless shrimp) | 1000(Headless shrimp) |

Input material temperature (Central temperature)(℃) | <10 | <10 | <10 |

Output material temperature (Central temperature)(℃) | -18 | -18 | -18 |

| The temperature of cold air circulation when unloading material(℃) | -35±2 | -35±2 | -35±2 |

| Freezing time (min.) | 10~60min.adjustable | ||

| Refrigerant | R717 or R22 or R404A | ||

| Cooling capacity for the machine(-40℃) (kW) | 89 | 146 | 260 |

| Installed power ( Kw) | 8.1 | 15.7 | 28.6 |

The overall size of the freezing room (L×W×H)(m) | 10.8×2.5×2.0 | 13.5×2.5×2.0 | 19.8×2.5×2.0 |

| Total length of equipment (m) | 12.8 | 15.5 | 17.4 |

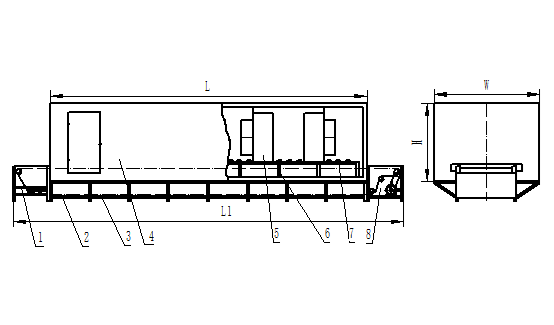

Schematic diagram of BS series Sea food freezing machine

Front device of Sea food freezing machine 2. External frame of Sea food freezing machine 3. Conveying steel belt of Sea food freezing machine 4. Insulated storage body of Sea food freezing machine 5. Evaporator 6. Internal storage support 7. Air guiding device 8. Rear device of Sea food freezing machine

Retains nutrients: Freeze-dried food retains up to 97% of its nutrients, including vitamins, minerals, and antioxidants. Long shelf life: Freeze-drying removes the potential for bacterial growth, so freeze-dried food can last for years. Maintains flavor and texture: Freeze-drying preserves the original shape, flavor, and texture of food. Sustainable: Freeze-drying reduces food waste and transportation and storage costs.

Freeze drying works by first freezing a substance, then lowering the pressure around it to a vacuum, which allows the frozen water to directly transition from a solid (ice) to a gas (water vapor) through a process called sublimation, effectively removing the water content without going through a liquid phase, thus preserving the material's structure and properties; this is often used to preserve food, pharmaceuticals, and biological samples by significantly extending their shelf life.

We Dalian Iceberg produce and supply freeze drying equipment with the below types and sizes: 1)Type: Industrial scale of freeze dryers with internal assembly of vapor trap(s) with separate condensers performing the functions of alternative vapour trapping and de-icing Sizes: A50, A75, A100, A125 and A200 2)Type: Pilot Freeze-dryers with one-time condenser Size: A5, A10, A20, A30 We can also develop other model of pilot freeze-dryers according to customer’s demands

It is 120-150 days in Europe and the United States, and 90-120 days in other regions.

Within 24 hours

The following 14 items of supplies are included in the contract price offer: 1) Drying chambers (with already integrated internal packages of the heating plates and the condensers) 2). Hot water system 3). Vacuum system with units for initial evacuation and vacuum maintaining 4). Ammonia circulation system 5). Alternative de-icing system 6). Pneumatic system 7). Cooling system (cooling tower) 8). Control centre with control panels and computer 9). Freezing tunnels 10). Rail system 11). Trolleys 12). Trays 13). Connecting pipes, pipe fittings and valves for systems 14). Cables, wires, shielded control lines, etc. for all systems We can also add other equipment according to customer's request.