Alternative vapor trap freeze dryer

The advantage of vacuum freeze-dried products

1. Under the condition of low temperature vacuum drying, keep the natural activity of material

2. Natural fresh color, aroma and nutritional value retained Shape and texture of fresh product is maintained, concentrated fresh flavor in finished product.

3. No additives or preservatives are used-finished product is all natural

4. Low moisture, light weight, easy to carry and keep a long shelf life

5. Spongy structure, add water back, easy recovered in short time

Freeze dried food

Freeze dried fruit

Freeze dried vegetable

Freeze dried sea food

Freeze dried powder

The technical data of Model A series- Freeze dryer using alterinative vapor trap

| Standard type for industrialized production | ||||||

| Model | A25 | A50 | A75 | A100 | A125 | A200 |

| Loading capacity (kgs/batch) | 330 | 660 | 990 | 1320 | 1650 | 2640 |

| Nominal total loading area of heating plates(㎡) | 25 | 50 | 75 | 100 | 125 | 200 |

| Max.capacity of vapor condensing (kg/h) | 57.5 | 115 | 173 | 230 | 280 | 450 |

| Operating temperature of heating plates (℃) | 30~120 | 30~120 | 30~120 | 30~120 | 30~120 | 30~120 |

| Nominal working pressure (Pa) | 30~120 | 30~120 | 30~120 | 30~120 | 30~120 | 30~120 |

| Evacuating time to reach within 133Pa with empty loading (min.) | 15~20 | |||||

| Required peak cooling capacity at -40℃(kw) | 45 | 85 | 132 | 180 | 217 | 350 |

| Max.vapor consumption of 0.7 MPa (kg/h) | 70 | 135 | 200 | 240 | 400 | 650 |

| Installation power (KW) | 30 | 55 | 68 | 86 | 55 | 80 |

Model A series -Combination type-Freeze dryer using alterinative vapor trap

| Combination type for industrialized production | ||||||

| Model | 2XA25 | 2XA50 | 2XA75 | 2XA100 | 2XA125 | 2XA200 |

| Loading capacity (kgs/batch) | 660 | 1320 | 1980 | 2640 | 3300 | 5280 |

| Nominal total loading area of heating plates(㎡) | 50 | 100 | 150 | 200 | 250 | 400 |

| Max.capacity of vapor condensing (kg/h) | 115 | 230 | 350 | 460 | 560 | 900 |

| Operating temperature of heating plates (℃) | 30~120 | 30~120 | 30~120 | 30~120 | 30~120 | 30~120 |

| Nominal working pressure (Pa) | 30~120 | 30~120 | 30~120 | 30~120 | 30~120 | 30~120 |

| Evacuating time to reach within 133 Pa with empty loading (min.) | 15~20 | |||||

| Required peak cooling capacity at -40℃(kw) | 80 | 158 | 240 | 320 | 360 | 650 |

| Max.vapor consumption of 0.7 MPa (kg/h) | 120 | 220 | 360 | 480 | 700 | 1150 |

| Installation power (KW) | 50 | 89 | 90 | 115 | 115 | 165 |

The characteristics of Alternative vapor trap freeze dryer

The trap is built into the bottom of the drying chamber and is equipped with a dual-chamber steam condenser continuous deicing (CDI). When the right condenser in the cabin begins to melt, the condenser sealing door panel in the cabin moves from the left to the right, closing the right condenser, and the left condenser communicates with the cabin to capture water vapor. The negative pressure water vapor on the right side of the cabin is connected to the ice melting tank and enters the right condenser in the cabin that has been sealed by the sealing door panel, melting the thin ice on the tube bundle into water, and flows into the ice melting tank through the lower part of the same pipeline. After the right condenser completes ice melting, it turns to the left side to melt ice, realizing alternating ice melting of the two traps. During the entire freeze-drying process, no additional time is required for separate ice melting, which helps to increase production to a certain extent.

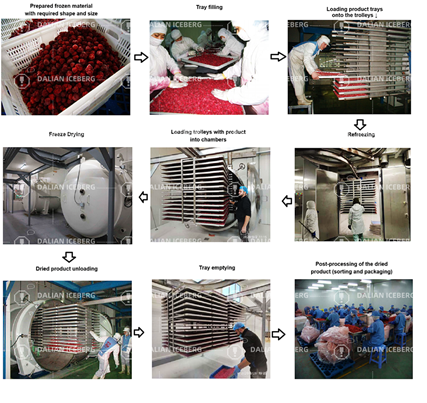

Alternative type vapor trap freeze dryer process

Other systems of Alternative type vapor trap freeze dryer

Company profile

Dalian Iceberg Freeze Drying Technology Co., Ltd. is specialized in the research, design and manufacture of Alternative type vapor trap freeze dryer and food individual quick freezing equipment. Alternative type vapor trap freeze dryer researched by the Company with foreign advanced technology has reached the international advanced level. The Company's products scatter about the whole country, and even are exported to Japan.

The Company has the strong management capacity of set engineering design and installation.In these years, Alternative vapor trap freeze dryer undertaken by the Company all have been in good quality,with short construction period and low integrated cost, thus winning the users' praise and recognition.

That 'Integrity, Quality and Credit' is our service tenet. We are willing to join hands with more foreign and domestic friends for common development based upon mutual benefit.

FAQ

Why freeze dry?

Retains nutrients: Freeze-dried food retains up to 97% of its nutrients, including vitamins, minerals, and antioxidants.

Long shelf life: Freeze-drying removes the potential for bacterial growth, so freeze-dried food can last for years.

Maintains flavor and texture: Freeze-drying preserves the original shape, flavor, and texture of food.

Sustainable: Freeze-drying reduces food waste and transportation and storage costs.

Retains nutrients: Freeze-dried food retains up to 97% of its nutrients, including vitamins, minerals, and antioxidants. Long shelf life: Freeze-drying removes the potential for bacterial growth, so freeze-dried food can last for years. Maintains flavor and texture: Freeze-drying preserves the original shape, flavor, and texture of food. Sustainable: Freeze-drying reduces food waste and transportation and storage costs.

Freeze drying works by first freezing a substance, then lowering the pressure around it to a vacuum, which allows the frozen water to directly transition from a solid (ice) to a gas (water vapor) through a process called sublimation, effectively removing the water content without going through a liquid phase, thus preserving the material's structure and properties; this is often used to preserve food, pharmaceuticals, and biological samples by significantly extending their shelf life.

We Dalian Iceberg produce and supply freeze drying equipment with the below types and sizes: 1)Type: Industrial scale of freeze dryers with internal assembly of vapor trap(s) with separate condensers performing the functions of alternative vapour trapping and de-icing Sizes: A50, A75, A100, A125 and A200 2)Type: Pilot Freeze-dryers with one-time condenser Size: A5, A10, A20, A30 We can also develop other model of pilot freeze-dryers according to customer’s demands

It is 120-150 days in Europe and the United States, and 90-120 days in other regions.

Within 24 hours

The following 14 items of supplies are included in the contract price offer: 1) Drying chambers (with already integrated internal packages of the heating plates and the condensers) 2). Hot water system 3). Vacuum system with units for initial evacuation and vacuum maintaining 4). Ammonia circulation system 5). Alternative de-icing system 6). Pneumatic system 7). Cooling system (cooling tower) 8). Control centre with control panels and computer 9). Freezing tunnels 10). Rail system 11). Trolleys 12). Trays 13). Connecting pipes, pipe fittings and valves for systems 14). Cables, wires, shielded control lines, etc. for all systems We can also add other equipment according to customer's request.